Every Day Brings a Fresh Challenge for Pump Expert Dean Muir

Get Inspired

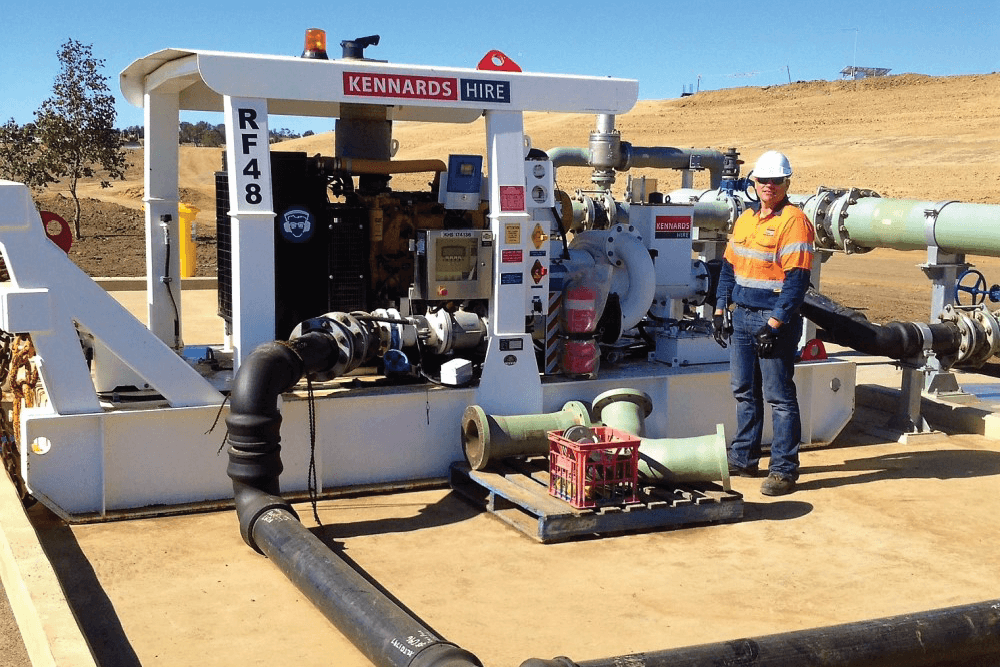

A throwback to a job in regional QLD with one of his favourite pumps – a High Head Mining Pump complete with remote start/stop & digital flow metre.

Every Day Brings a Fresh Challenge for Pump Expert Dean Muir

When Dean Muir heads into work at Kennards Hire, he is a man with a plan, but he always leaves room for the unexpected.

“If there is a crisis or customer who needs an immediate solution, we need to be flexible and get straight on the case,” he said.

“Our job is to solve problems for our customers in Australia and New Zealand. I love talking to our customers to really understand their situation, and what’s required to get the job done.”

Experience and expertise assist in problem solving

As the company’s national operations specialist for pumps, Dean’s role gives him a foot in both the sales and operations side of the hire business, which suits him down to the ground.

He likes the problem solving, but he also understands that he works in a business that’s committed to being the best in hire, not the biggest. So decisions are often made based on long-term thinking.

"I’m always looking at opportunities to expand on our capabilities, whether that’s new practices or new equipment.”

"I’ve learnt so much and I love sharing that knowledge with new colleagues as they come into the business. They can learn from my hands on experience. I want them to see the hire industry as an interesting, challenging career rather than just a job.”

Dean also knows nothing is accomplished without the teamwork at Kennards Hire.

“There is a really strong network of people who want to help each other and to help the customer. It’s like being in a rugby team; we’re all different, with different skills. One thing I’ve learnt over the years is that when you help one another, it all comes together.”

Dean's most challenging job

In mid-2020, a water authority contacted Dean about remedial works on a 1950s irrigation channel that supplied farms. They needed to bypass 120 megalitres of water per day for three weeks, while they installed new automated gates to irrigation channels.

After receiving the call, Dean investigated and recommended two silent 12” pumps capable of pumping up to 600 litres per second and four 8” pumps capable of pumping up to 150 litres per second each. The combination provided backup and built-in redundancy for the flow requested.

Within two weeks, Kennards Hire had purchased the equipment required for the job, and Dean's team helped contractors set them up over four days.

"Then we monitored them via telemetry from Brisbane. Pressure transducers enabled us to read the levels within the channels and automatically turn on additional pumps to cater to the changing flow," he said.

"This kept the workers downstream out of danger from a potential wall of water breaching the barrier.”

"Knowing that my experience and knowledge lead to a successful outcome for the customer meant that it was a really satisfying project for me. The customer was able to maintain water supply to the irrigators and that’s a job well done!"